从事装配设计 (DfA) 的制造商一直在寻找简化装配过程、降低成本和提高效率的方法,因此我们在BricsCAD Mechanical中引入了装配检查工具。 虽然传统上,工程师会在原型阶段测试产品的装配可行性 – 通常需要多次迭代并增加成本 – 但使用 BricsCAD Mechanical 的用户可以从装配检查工具中受益。

装配检查工具由Bricsys 和 Flanders Make 合作开发,是一种原生的深入装配评估工具,可帮助机械设计工程师在设计阶段验证他们的装配。 该工具模拟装配过程并评估各种装配标准,全面评估装配的能力并帮助设计师尽早发现和纠正潜在的设计错误。 这确保了装配过程的高效,从而减少了生产阶段的问题。

让我们仔细看看该工具的工作原理。

在 BricsCAD Mechanical 中验证装配体

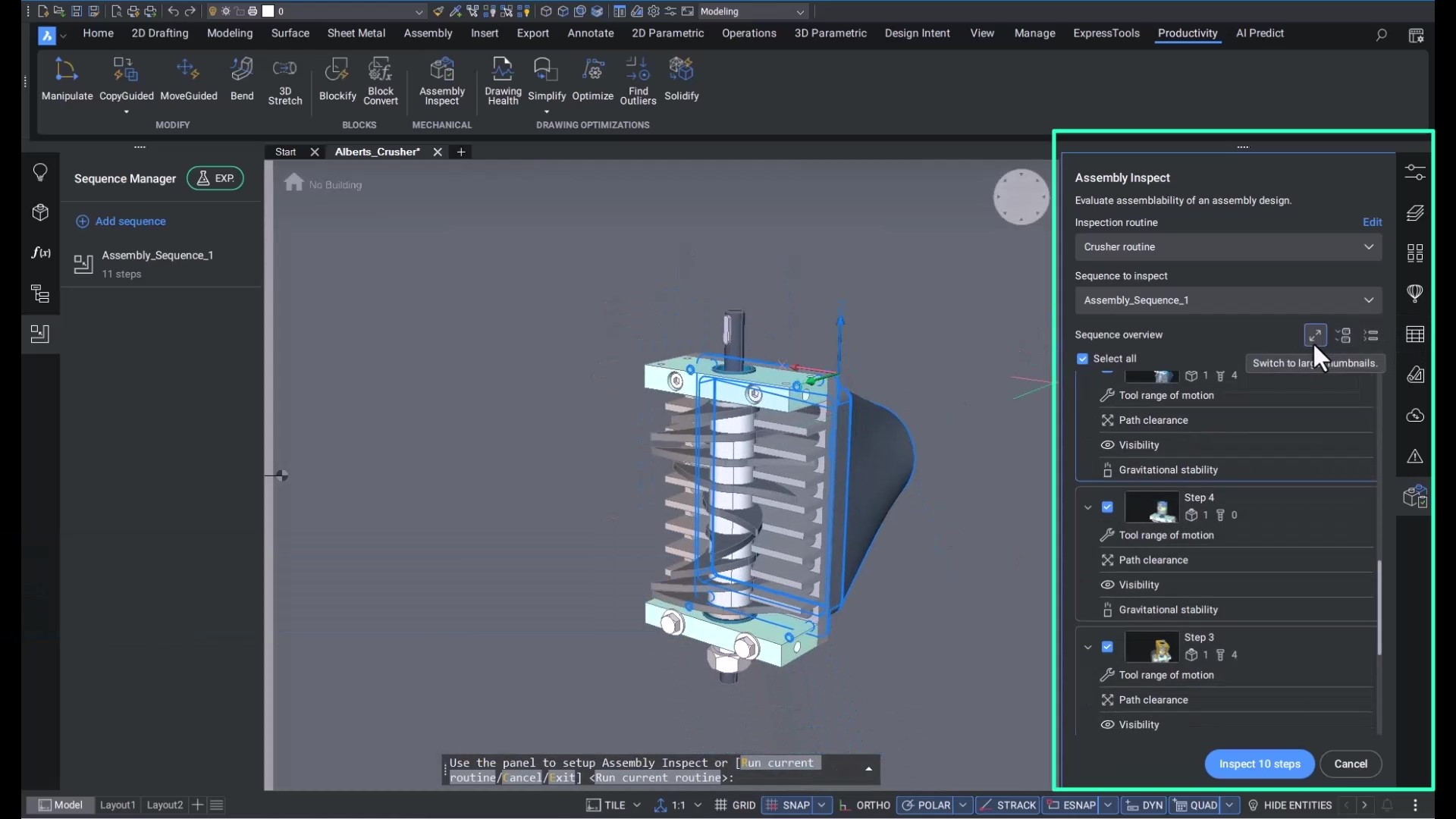

在此示例中,您可以看到 BricsCAD Mechanical 中的装配检查工具应用于破碎机组件。 使用 BMASSEMBLYINSPECT 指令打开该工具。 您可以指定要检查的装配顺序,并使用相应的缩略图和“眼睛”图标快速查看该顺序。

每个步骤都显示了适用的组装标准,并在例程中指定。

评估装配标准

您可以评估单个批次中每个步骤的所有标准,或者如果您想采用更细致的方法,则可以使用每个标准和步骤旁边的“检查”按钮。

一旦装配检查工具完成其计算,它就会向您显示任何潜在的装配问题。 然后,您可以深入了解细节,了解问题所在,以及如何解决它。

刀具的活动范围

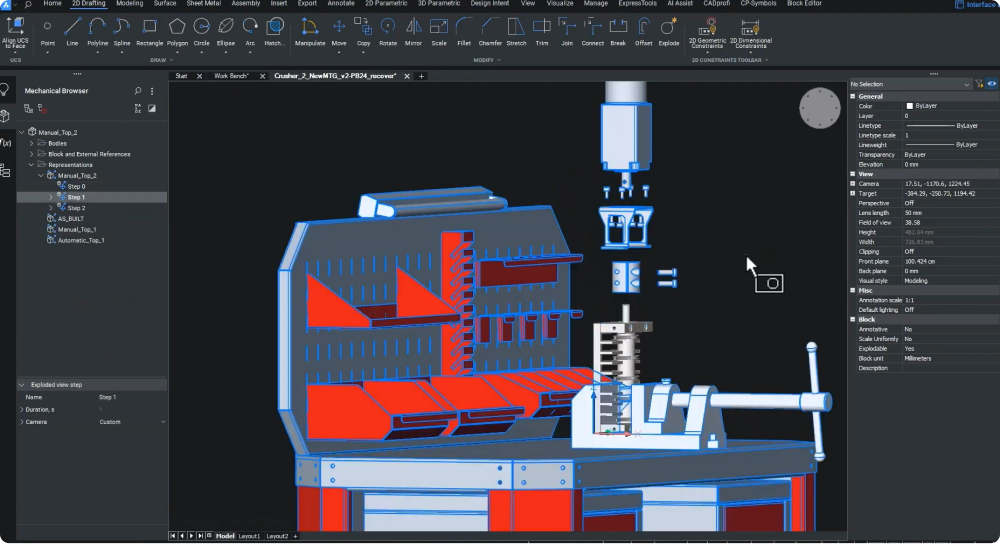

在此示例中,我们在步骤 2 中检查了工具的运动范围。仔细观察后,我们可以看到没有问题,因为可以使用长臂固定紧固件,而短臂可以用于最后几次旋转。

在步骤 3 中,我们可以看到没有 360 度的运动范围,因此虽然此步骤可能可行,但我们可以通过提供不同的工具来提高装配操作员的效率和人体工程学。

重力稳定性

该工具还允许您研究重力稳定性标准。 在步骤 6 中,您可以看到格栅组件不稳定,因此一旦装配操作员松开零件,格栅就会掉落。

观看视频!

如果您好奇并想看看装配检测工具的实际运行情况,请关注Bricsys YouTube 频道观看演示。

试用 BricsCAD Mechanical

免费试用 BricsCAD Mechanical 30 天,了解装配检测等工具如何帮助您走上最快的生产之路!