제조 및 조립 업계에서 조립 지침을 효과적으로 전달하는 것은 기술 문서의 품질에 달려 있습니다. BricsCAD® Mechanical V24.2의 출시로 사용자는 검증된 설계를 손쉽게 문서화할 수 있는 종합적인 툴킷의 이점을 누릴 수 있습니다.

상세하고 정확한 기술 문서 작성

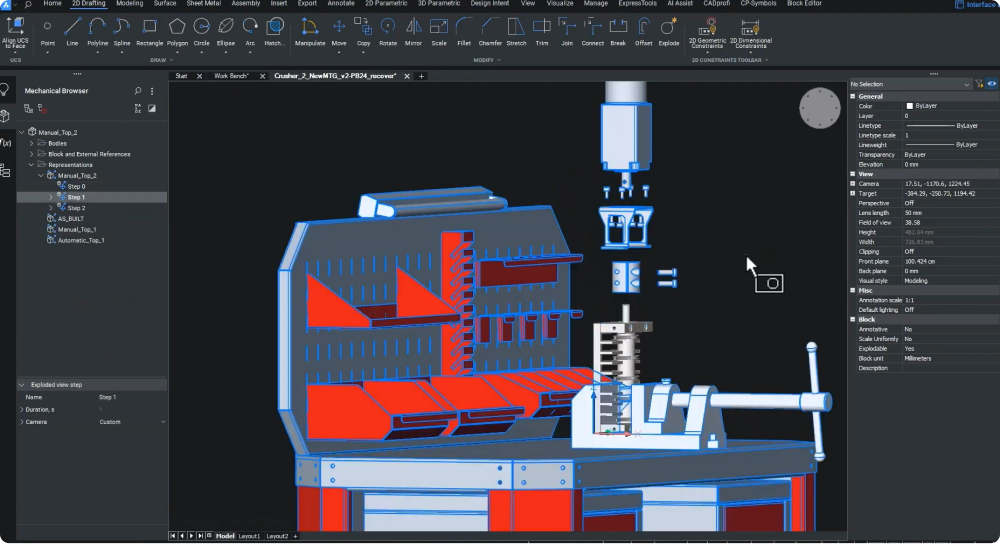

BMEXPLODE 명령을 사용하여 기술 문서에 대한 세부 단계를 빠르게 생성할 수 있습니다. 엔지니어, 테크니컬 일러스트레이터, 마케팅 전문가 등 누구나 BricsCAD Mechanical의 강력한 기능을 활용하여 매우 효과적인 조립 설명서 및 유지보수 안내서를 제작할 수 있습니다.

V24.2에서는 현재 시퀀스 단계에 기반한 새로운 분해 보기 옵션을 포함한 향상된 기능을 제공하기 위해 BMEXPLODE 명령을 업데이트했습니다. 이 버전은 또한 최종 입력 단계에서 진행률 표시줄을 숨겨 사용자 환경을 고려하여 명확성을 높였습니다.

V24.2에서는 사용자가 어셈블리 프로세스의 각 특정 단계에 대해 개별 어셈블리 구성 요소를 수동으로 배치할 수 있습니다. 집중적인 주의가 필요하다는 점을 인식한 BricsCAD Mechanical V24.2는 사용자가 개별 단계에 대한 맞춤형 카메라 뷰를 설정할 수 있어 메시지를 정확하게 전달하는 데 큰 도움이 됩니다.

SVG로 문서 내보내기

문서 작성에는 워드 프로세싱, 데스크톱 게시 및 레이아웃 애플리케이션 프로그램이 필요한 경우가 많으므로 단계 보기를 내보내는 데 가장 적합한 형식은 SVG(확장 가능한 벡터 그래픽) 형식입니다. SVG는 확장성, 최적의 파일 크기, 편집 기능, 주요 스타일 제어 등 사용자에게 여러 가지 이점을 제공합니다.

BricsCAD Mechanical에서 파일을 SVG 형식으로 내보내는 것은 EXPORTSVG 명령으로 간단합니다. 사용자는 상세한 수동 단계 또는 자동 분해 보기를 생성하는 옵션을 통해 문서화 프로세스의 유연성을 확보할 수 있습니다. BMEXPLODE 명령을 사용하고 자동 옵션을 선택하면 사용자는 제품 분해에 대한 일반화된 보기를 볼 수 있습니다. 조립 중 부품의 경로와 같은 세부 정보를 추가하려면 BMTRAILINGLINES 명령을 사용하여 후행선을 추가하면 됩니다.

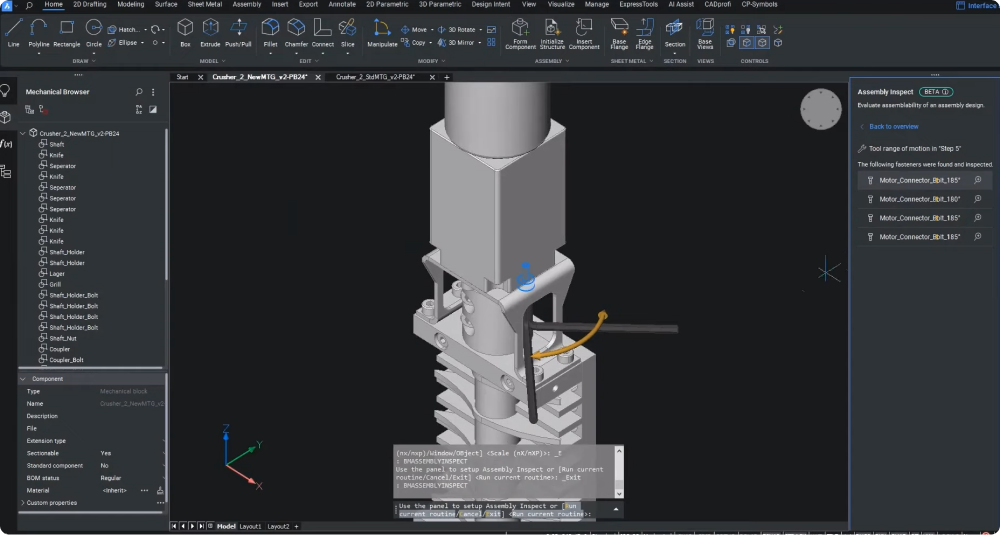

최적의 조립 방향 강조 표시

검사 중 중력 안정성 결과를 통해 학습하면 조립 지침을 최적화하는 데 도움이 됩니다. 예를 들어, 스텝이 똑바로 세워진 방향에서 불안정한 결과를 초래했다고 가정해 보겠습니다. 이 경우 패스너를 아래에서 위로 삽입할 수 있도록 어셈블리의 방향이 평평한지 확인해야 할 수 있습니다.

수동 상세 분해도와 같은 도구를 사용하면 가상 환경(예: 작업대)을 만들어 최적의 어셈블리 방향을 강조할 수 있습니다. 마지막 단계는 SVG 파일을 조립 매뉴얼 문서로 가져오고, 조립 단계를 문서화하고, 조립에 이상적인 방향과 같은 필수 세부 사항을 포함하는 것입니다.