‘To be exact’ is the most important core value for Netherlands-based shipbuilding company Asto Shipyard. Founded in 1956, Asto Shipyard is the go-to total solution for construction, finishing, maintenance, and repair of inland vessels and shipping-related projects. To ensure the highest standards of accuracy, Asto Shipyard uses BricsCAD Mechanical to design all structural and mechanical parts.

From the engine room to complete ship construction

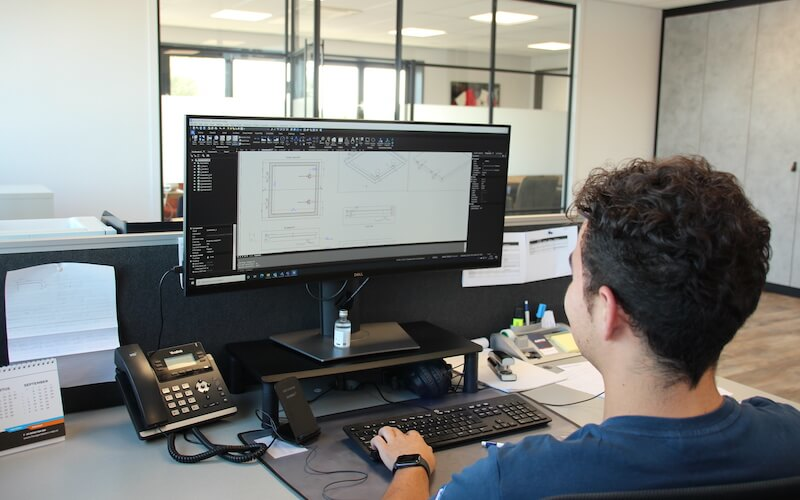

Engineer Melvin Hamar de la Brethonière, and project manager Stijn Buijks from Asto Shipyard explained why it is critical for shipbuilders ‘to be exact’.

"We are very busy right now," said Hamar. "About 35 people work at Asto and we often hire temporary workers to support us, so we can have up to 150 people onsite during our busiest times. Our clients are mainly shipping companies, government services, and private individuals who rely on us to build and maintain their vessels.”

“We offer a total solution for the entire process from design to delivery, and we also manage parts of the total construction," added Buijks. "For example, there are customers who buy a hull themselves and come to us to complete the engine room.”

Drawings in shipbuilding

Although most designs in the shipbuilding industry are created in 2D, Asto Shipyard started incorporating 3D modeling into their designs to prioritize innovation and accuracy.

"Most of the drawings we receive and provide to the workshop are in 2D, and even complex matters such as ship engines are largely delivered in 2D,” said Buijks.

“Even so, as a company we felt it was time to start using 3D modeling. In 3D we can draw parts more precisely, and we noticed that a 3D model is more appealing in the minds of our clients. To put simply: it sells better,” Buijks explained.

BricsCAD Mechanical instead of Inventor

Local BricsCAD reseller CADKoop recommended BricsCAD Mechanical design software to the team at Asto Shipyard for structural and mechanical drawings, and it turned out BricsCAD Mechanical was exactly what the company was looking for.

“With BricsCAD Mechanical we can easily draw our popular parts such as shutters and air vents in 3D,” said Hamar. “We often use the Sheet Metal functionality, so it is very convenient that the different profiles are all present in BricsCAD. Thanks to the Communicator for BricsCAD, we can also easily open and edit other files such as .ipt and STEP files," Hamar added.

“What we also like is that we can buy BricsCAD Mechanical with maintenance, making it a much more cost-effective alternative to Autodesk’s® Inventor for example.”

New possibilities in 3D

"Now that we are drawing in 3D, it is easier to reuse drawings or parts of drawings,” said Hamar. “We are creating a library of our most common parts, and because every ship is different, we need to adapt these parts quickly and easily. Our plan is to parameterize other elements such as stairs, shutters, and penetrations too, which will save us a lot of time.

“We’ve also noticed that drawing engine rooms in 3D is more precise. These are often small spaces with many machines so it's important all measurements are correct. The process is smoother and more accurate in 3D, and much clearer for our client too.

“BricsCAD Mechanical has enabled our team to set even higher standards for structural and mechanical drawings, and we are only getting started, added Hamar. “There are many benefits of 3D modeling for shipbuilding that we are yet to take advantage of.”

Netherlands

Shipbuilding

Asto Shipyard

- www.astoshipyard.nl