Picture a world where you no longer need to place an order on Amazon and wait days for delivery, or head down to your local mall and spend hours tramping between shops. You simply sit on your sofa, download a model and 3D print it on your desk while you drink your morning coffee. Well, that's the future 3D printing enthusiasts would have you believe but how far is this from reality in today's world?

TL;DR:

3D printers can print in a wide range of materials...

plastic, concrete, biological material, chocolate, etc. But can not reproduce materials such as fiberglass and wood. They are cheap and convenient for small batch productions and prototypes, but not cost effective for high volume. 3D prints can be very large, but large printers are also expensive. They can produce complex object shapes but not items made with combinations of materials. They might not be family friendly due to toxic fumes and noise pollution.

Prototyping

With regards to creating prototypes and scale models, 3D printing wins hands down on cost and time. If testing out a new handle for an ergonomic spoon, a few copies can be printed in a few days and tested there and then. No need to wait around for expensive tooling to cast prototypes, or to make crude models from foam and automotive styling clay.

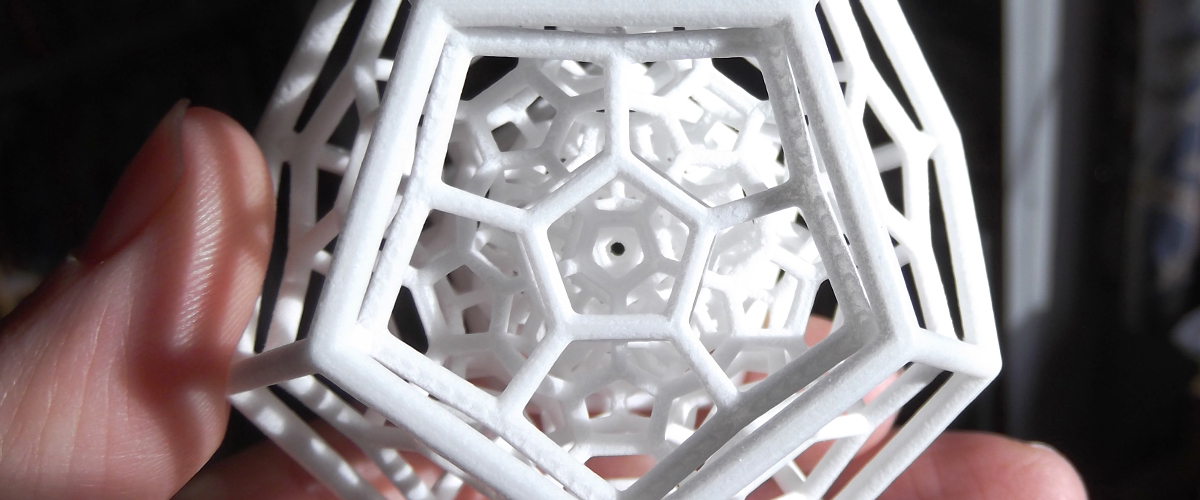

Shape and form

threeASFOUR 3D printed Geometric dress. Photo link: 3Dprint.com

3D printing also offers the unique possibility of creating objects that would be otherwise impossible to produce using traditional methods. A quick google will bring up all kinds of weird and wonderful 3D printed shapes that could only previously be achieved with an extremely steady hand or would simply be completely impossible to manufacture. And, with 3D printing, there is no longer a need to worry about details, such as undercuts, which are potentially impossible when using more traditional methods.

Size

The maximum size of prints is one of the limitations of additive manufacturing. Until recently, this was a real problem. However, with 3D printers such as BAAM (Big Area Additive Manufacturing) from Cincinnati, which is capable of printing whole cars, a model spacecraft, and even, a strangely beautiful excavator, thanks to its 610 x 229 x 183cm (240 x 90 x 72") print area, things are changing. However, printers like this don't come without a hefty price tag!

3D Printed Excavator. Image Credit: Cincinnati

Materials

The material possibilities of additive manufacturing are ever expanding from extrusion methods such as heated ABS plastic and controlled, flowing concrete, to additive manufacturing that uses light. Such examples include metal, laser printers and more recently, the University of Michigan developed a way of extruding solid material from liquid resin. The characteristic "stripes" you find on 3D printing are gone, improving the strength of the material. They also claim it reduces the time it takes to print an object to 1% of that of traditional methods.

There have even been advances using biological materials to 3D print organs, clay has been used to 3D printed vases, whilst 3D printed edibles, such as cakes, and chocolates are seemingly here to stay.

3D printed sugar cubes. Image link: 3D Systems

However, there is a limitation on the types of materials that have 3D printing validity. Cotton and silk and organic, therefore, are not liquefiable and, much like carbon fiber, need to be woven. Paper and laminated wood are again, not readily reproducible in liquid form. 3D printed glass is currently rather stripey and unlikely to be replacing the glass in your windows any time soon. Whilst metal cabling is, in itself, extruded and then twisted, a manufacturing process that can not be improved with a 3D printer.

Mixing materials

One of the big limitations of 3D printers is material combinations. Currently, there are a large number of 3D printers on the market that can mix colored plastic, either by using different printing nozzles or by feeding different colors, at different times, through the same printing nozzle. There is even one: the Project Mjp 5600, that can mix different types of polymers to give different material properties. However, no 3D printer currently exists that can successfully print complex combinations such as plastic with an internal metal framework. Currently, existing 3D printers simply print material around a given component. Any such printers would likely need to use a range of printing techniques within the same printer.

Furthermore, each additional material that a 3D printer can use must be stored somewhere. Not particularly an issue if the 3D printer lives in a large warehouse but potentially problematic to have a cupboard full of different types of filament, for every 3D printing eventuality. Particularly when people are living in increasingly smaller and smaller living spaces.

Moreover, heat expansion and contraction are a consideration. You might have noticed that cooling plastic has a tendency to contract and bend during 3D printing. Imagine the effects of a combination of materials with a wide-ranging difference between melting points...

Cost factor

Then there is the cost relative to high volume production. Sure, if you're only making a small batch of 100 or fewer items, it might be cheaper and simpler to 3D print. But if you're making items in the 100,000s then more traditional methods will probably work out better value for money. 3D printing can also be a lot slower than traditional manufacturing methods.

Noise and toxicity

Finally, as anyone who has ever played around with a 3D printer will be more than aware: 3D printers emit known toxic fumes and are typically noisy. They are something that you might want in your garden shed or your garage, but not in the living room with your kids.

In conclusion

Whilst additive manufacturing technologies have created some really weird and wonderful things, it is unlikely that manufacturing companies will be closing down any time soon, given the limitations of 3D printing and the costs.