Designing a model for 3D printing can seem like a daunting task. But it doesn't have to be. While there is no one-size-fits-all approach that beginners can follow to create a successful design, there are some do's and don'ts that are worth knowing to lower the chances of producing a failed print.

Do's of Creating 3D Printing Models

Do consider wall thickness

One of the most common causes of unprintable 3D model designs is wall thickness. Wall thickness is defined as the distance between one surface of a 3D model and its opposite surface. But why is this important? When the wall is too thin, it can make your design unprintable or incredibly fragile. If it's too thick, it might cause too much internal stress and result in the model cracking or breaking.

In short, it's important that you ensure that you get the wall thickness just right. Take note that the correct wall thickness of a model will depend on the material and size of the design. Here is a list of the minimum wall thickness for some of the most popularly used 3D printing materials:

- ABS -- 1.5mm

- Aluminium -- 1mm

- Brass -- 0.6mm for a natural finish, 0.8mm for gold and color-plated finishes

- Gold -- 0.8mm

- Silver -- 0.6mm for a gloss finish, 0.8mm for a high gloss finish, 1mm for small 3D models such as ring

- Standard Resin -- 1mm, but may increase as the 3D design becomes larger in scale.

- Titanium -- 0.5mm

- TPU -- 1.5mm

Do get clearances right

If you're designing a model that features interlocking parts, then you need to make sure that you design proper clearances to make sure everything fits just right. This means that parts should be designed to feature enough space or gaps between them to account for possible deviations in their dimensions.

3D printing is not as precise as other manufacturing methods. For example, a part may feature several small artifacts on its surface that can affect the fit between pieces.

Experts recommend that you learn your 3D printer's tolerances to avoid poorly fitting parts. One tip for creating correct fit tolerances is to use a 0.2mm offset if you want to create a tight fit such as connectors. Use a 0.4mm offset if you want to create a loose fit like with hinges or box lids. Of course, it's better if you run some tests as well to determine what the correct fit tolerance is for the 3D printing model that you are creating.

Do follow software guidelines

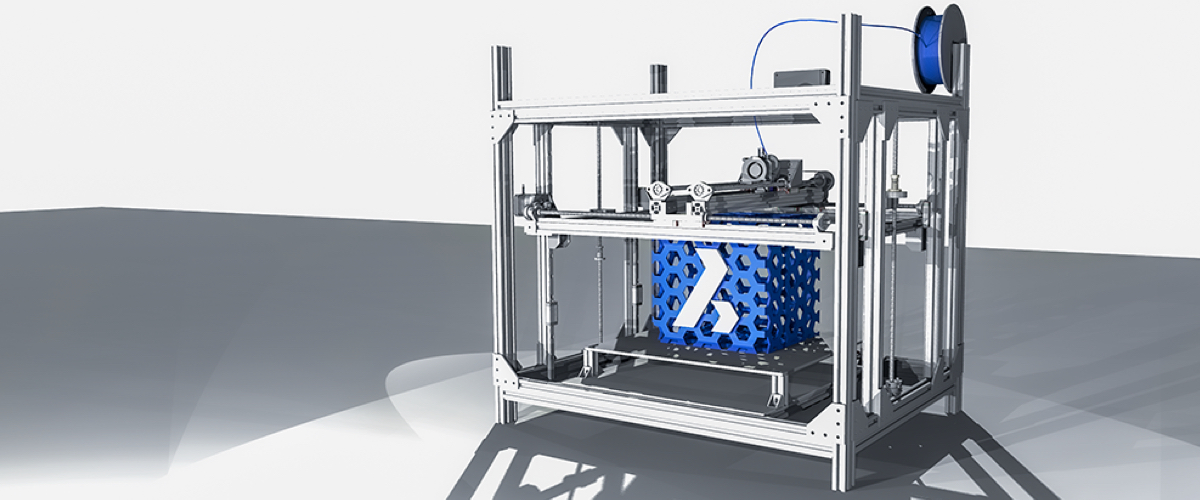

There are a variety of 3D modeling software packages available. Some are designed to be used by professionals that require a bit of expertise on the side of the user such as BricsCAD Pro. For example, some programs will require the user to manually set wall thickness. And some which require further file preparation.

Whatever program that you end up using, you need to make sure to read the program's guidelines as well as watch some tutorials before you start designing your model. This way, you avoid making avoidable mistakes from the get-go which not only saves you time but also saves you from producing failed prints, which is a waste of material and money as well.

Do know your printer's limitations

Understanding what your 3D printer can and cannot do is just as important as knowing how to properly use your 3D printing software.

For example, an FDM 3D printer is best suited for creating large objects where surface finish is not an important consideration. It's a good option if you want to create parts that feature a mechanical function such as stands or holders.

However, an FDM printer is not ideal for printing models that are smaller than tens of millimeters because the quality of the print will be subpar. If you want to print designs with extremely fine detail, you're better off choosing a resin 3D printer (i.e. SLA) than using an FDM 3D printer.

Don'ts of Creating 3D Printing Models

Don't ignore material guidelines

While a lot of the 3D printing materials available are plastics, that doesn't mean that they are interchangeable.

Each 3D printing material in the market is different; all of them have unique properties. Some are light, others are heavy. Some are brittle while others are flexible. Some produce a smooth surface while others are rough. There are even some 3D printers that can print organic material.

Because of each material's specific strengths and weaknesses, it is important that you understand what it can and cannot be used for. It is also important that your design should incorporate the characteristics of the material you have in mind. For example, if you want to produce a 3D printing model made out of steel, you need to consider its design limitations. Unsupported overhangs made out of steel need to have a wall thickness of 6mm; otherwise, they will collapse.

Here's another example: flexible materials aren't ideal for models with small details. So, make sure that your design doesn't have any small features if you're using this type of material.

Keep in mind that manufacturers of 3D printing materials also provide printing instructions and tips. Make sure that you refer to them while you're designing your model. Doing so will decrease the chances of your print turning out wrong.

Don't forget the 45° rule

In 3D printing, you create objects layer by layer from the ground up. What this means is that overhangs -- features that hang in mid-air -- don't retain their shape too well. They are easily deformed. To avoid this, you need to include support structures in your design.

However, support structures increase the time spent printing the model. It also impacts the length of the post-processing time because removing them can be time-consuming. Moreover, they can leave ugly marks on your 3D printing model. To avoid this inconvenience, it's best to design with the 45° rule in mind: your overhangs should not exceed 45° if possible. If they do, you'll need to incorporate support structures in your design.

Bottomline

There are thousands of free 3D models that you can download from sites like Thingiverse or GrabCAD. And you likely started out doing that. While there's nothing wrong with it, creating your 3D model and then bringing them to life is what makes this disruptive technology so great. It allows anyone to have that creative freedom.

Of course, not all designs will translate well to 3D printing. Some will turn into failed prints. But if you follow the do's and don'ts listed above, you just might be able to create something that will transform your world. And maybe even ours.