Working from Estonia, Makespace's expertise in build-designs with engineered structural timber has accomplished construction projects for public, commercial and residential buildings.

The company's engineering and structural design work ranges from atrium beams and engineered trusses to structural and private home designs for design-for-manufacture (DfMA) and off-site construction.

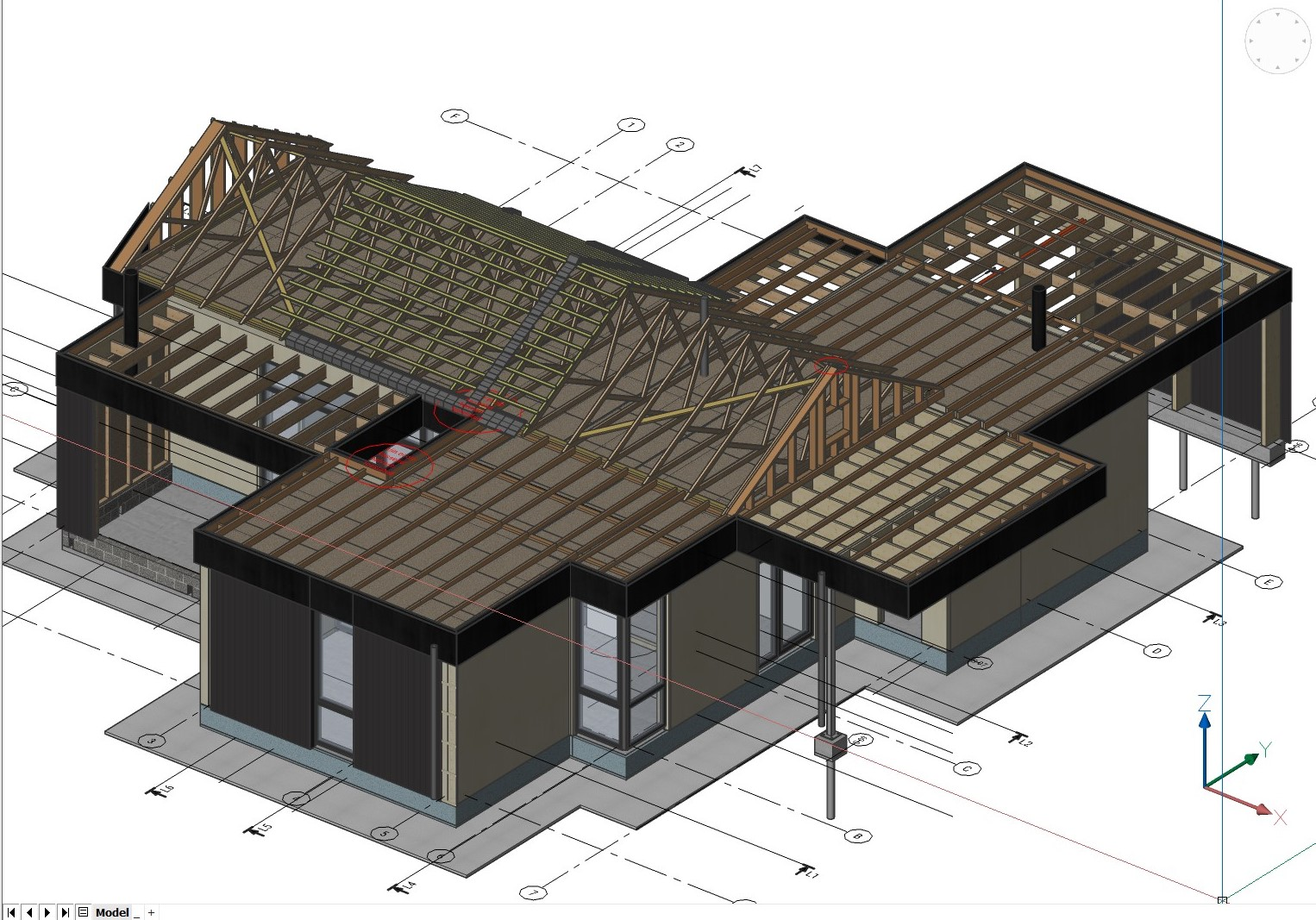

Makespace delivers highly accurate 3D models directly to the factory, with detailed design elements and a complete BOM, ready for their clients' workflows.

The Challenge

The journey for Makespace started when their design team wanted to develop 3D drawings with the level of detail required for their collaborations on design-to-manufacture workflows with architects, structural engineers and building owners.

Makespace's team are accomplished CAD designers, so harnessing their knowledge of this design environment and equipping the team with innovative CAD tools was critical.

For the design-to-manufacture process, the 3D designs and deliverables from Makespace must also bring high value to all project stakeholders. This is true from the first conceptual visualization for the client to capturing the engineer's tolerances for manufacturing.

This means the team at Makespace prioritized a solution with advanced tools to design or model any changes quickly and efficiently to generate visualizations for the building owners. Equally, their next CAD solution had to deliver accurate mechanical and BIM data from models for final engineering, manufacturing and assembly.

The Solution

Makespace quickly gained productivity with BricsCAD due to the familiar CAD commands and user interface and its interoperability across BIM and Mechanical design tools in the same solution.

Laur Lõvi, a structural engineer at Makespace, had been creating models with their legacy-CAD software since 2010, so he first tried a version with BIM integration, but he felt there was not enough investment in the platform.

Laur tried other traditional BIM software, but it was different from the CAD system he used. He also found that the modeling needed to be more flexible for their workflows.

"The flexibility to model anything as solids, then classify them as needed, was another strength of BricsCAD and something that traditional BIM software doesn't support," said Laur.

Laur and his team were instantly familiar with the commands and user interface and got working quickly. In addition, the team maintained their workflow productivity because of BricsCAD's ability to migrate and transfer existing customizations and LISP routines.

Results

Laur Lõvi from Makespace identified some immediate reasons why BricsCAD Ultimate's CAD and BIM interoperability was the best choice for their projects with engineered structural timber and DfMA.

Visualization: collaborative design intent

Makespace found that 3D models for manufacturing or engineering are a more efficient way of communicating the design intent. 2D drawings do not offer a rich visual understanding, and customers need to experience how a design will look when constructed.

"I don't use 2D drawings all that much because 3D is much better for showcasing what I need," explained Laur. "Also, our fabrication clients only require 3D models and keep everything inside the model."

Makespace also uses Twinmotion in its design workflow to give its customers a real-time, immersive 3D visualization of the construction. The direct link between BricsCAD and Twinmotion keeps the models synchronized between the two applications, enabling Makespace's designers to edit their models and visualize design changes quickly.

Flexible 3D modeling

The most significant value Makespace identified for their design workflows is the ability to model freely and in accurate detail.

"It is important to me that I can model freely in BricsCAD," described Laur. "For instance, the ability to use the UNION command to join regions and 3D solids into a single entity."

Productivity and accuracy with AI

Propagate, a powerful and intelligent command, is one of Laurs' favorite features of BricsCAD, having first seen the capability when researching. Propagate saves a lot of time in the design process by allowing users to create typical high-level details and apply those details throughout the entire model.

"Then I stumbled upon Propagate in the Bricsys' videos about how to use it for structural elements. That caught my eye, and from there, I realized the possibilities with BIM - making any 3D solid and categorizing it as I want without any kind of limitations," recalled Laur.

Design-to-manufacture workflows

BricsCAD Ultimate enables Makespace to integrate the advanced CAD capabilities of BricsCAD Mechanical in the BIM environment. This integration was one of the key value aspects agreed on by the personnel involved in the purchasing decision.

"I got approval on BricsCAD Ultimate licenses just on its ability to integrate mechanical workflows into the engineering side," told Laur.

By choosing BricsCAD, Makespace could streamline its design processes on a familiar CAD platform with 3D capabilities and interoperability across the entire DfMA workflow.

BricsCAD Ultimate's interoperable CAD, Mechanical and BIM package has allowed Makespace to transition from 2D drawings and model freely and accurately in a CAD-based 3D environment with high levels of flexibility.

Makespace's designers can also add BIM and fabrication details to their models as the workflow demands, sending their 3D models directly to the factory for fabrication.

Taru, Estonia

AEC and Structural Design

Makespace OÜ

- www.makespace.ee